8 COST SAVING TIPS FOR YOUR PRINT MARKETING PROJECTS

Working closely with your printer at the start of a print project helps us save money and time. Here are eight things to think about when planning your next print job:

1. MAXIMIZE THE SHEET SIZE

When designing your print materials, aim to use as much of the paper sheet size as possible to minimize waste and reduce production costs. Adjusting the size of your artwork to fit efficiently on standard paper sizes can lead to significant savings. For example, if you’re printing cards, consider the dimensions in relation to the paper sheet size to maximize the number of cards per sheet and minimize waste.

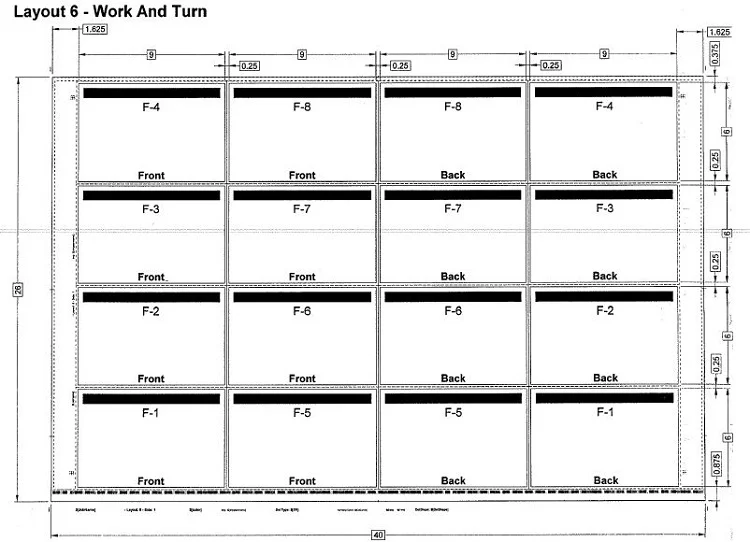

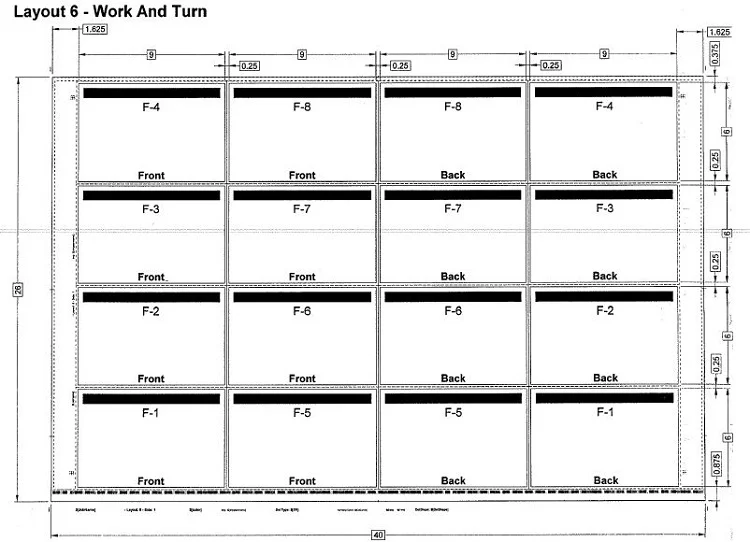

2. TAKE ADVANTAGE OF A WORK AND TURN

Utilizing a “work and turn” setup allows you to print both sides of your piece in a single run through the press, reducing the number of printing plates needed and eliminating the need for additional press setups. This method is cost-effective and efficient, especially for projects with consistent coating and scoring requirements.

3. PRINT 4-COLOR VS SPOT COLOR

While spot colors offer precise color matching, using 4-color process (CMYK) printing can be more cost-effective for projects that don’t require specific brand colors. By utilizing CMYK printing, you can avoid the additional costs associated with spot color inks and plates. However, if precise brand colors are essential, spot color printing may be necessary.

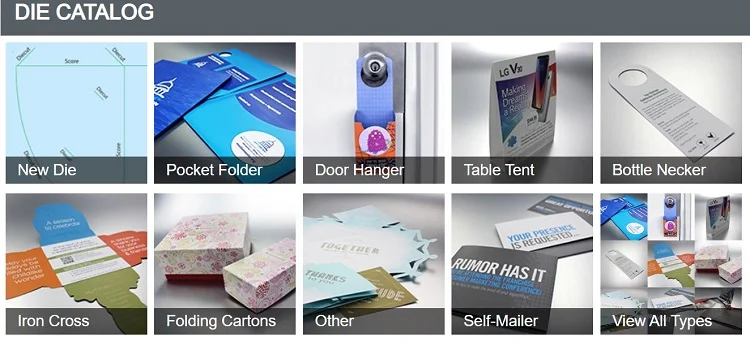

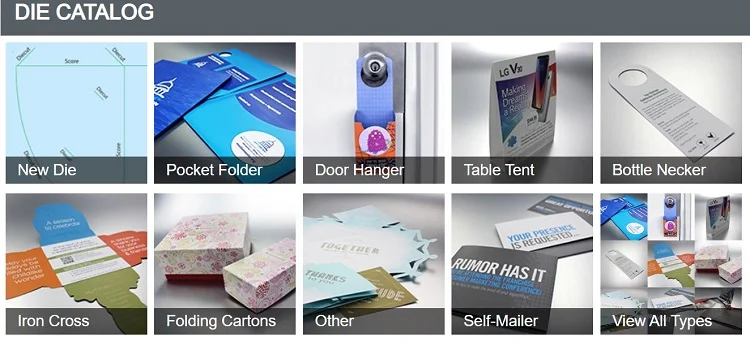

4. REUSE AN EXISTING DIE VS NEW DIE

If your printer has a library of pre-existing die patterns, consider using one of these designs to avoid the expense of creating a new die. Reusing an existing die not only saves money but also reduces the time and effort required for die creation and setup. Check with your printer to see if they have suitable die patterns available for your project.

5. CREATE MACHINABLE FOLDS

Design your folds to be machine-friendly, as machine folding is generally more cost-effective than hand folding. Standard folding machines can handle various fold types, such as roll, letter, gate, and double gate folds. By ensuring that your folds are machinable, you can streamline the production process and minimize labor costs.

6. USE MACHINE INSERTABLE ENVELOPES

Choose envelopes with machine-insertable flaps, such as commercial or wallet flaps, to simplify the mailing process and reduce labor costs. Machine-insertable envelopes are compatible with high-speed inserting equipment, allowing for efficient insertion of printed materials. Avoid envelopes with pointed, euro, or square flaps, as these may require hand-insertion and increase production time and costs.

7. CONSOLIDATE YOUR PRINTING

Plan and print a larger quantity of materials at once to take advantage of economies of scale and reduce setup costs. By consolidating your printing, you can save time and money on repeat print runs and benefit from bulk pricing discounts. Additionally, storing excess printed materials for future use can help optimize inventory management and further reduce costs.

8. CHOOSE PAPER WISELY

Selecting the right paper grade for your project can impact both cost and quality. Consider factors such as ink coverage, coating, and intended use when choosing paper. For example, opt for higher-grade paper for premium projects like annual reports, while choosing lower-grade paper for projects with heavy ink coverage to minimize costs. By choosing paper wisely, you can achieve the desired quality within your budget constraints.

Implementing these cost-saving tips can help you optimize your print marketing projects while minimizing expenses and maximizing efficiency.

Recent Posts

ONE STEP PRINT LLP

8 COST SAVING TIPS FOR YOUR PRINT MARKETING PROJECTS

Working closely with your printer at the start of a print project helps us save money and time. Here are eight things to think about when planning your next print job:

1. MAXIMIZE THE SHEET SIZE

When designing your print materials, aim to use as much of the paper sheet size as possible to minimize waste and reduce production costs. Adjusting the size of your artwork to fit efficiently on standard paper sizes can lead to significant savings. For example, if you’re printing cards, consider the dimensions in relation to the paper sheet size to maximize the number of cards per sheet and minimize waste.

2. TAKE ADVANTAGE OF A WORK AND TURN

Utilizing a “work and turn” setup allows you to print both sides of your piece in a single run through the press, reducing the number of printing plates needed and eliminating the need for additional press setups. This method is cost-effective and efficient, especially for projects with consistent coating and scoring requirements.

3. PRINT 4-COLOR VS SPOT COLOR

While spot colors offer precise color matching, using 4-color process (CMYK) printing can be more cost-effective for projects that don’t require specific brand colors. By utilizing CMYK printing, you can avoid the additional costs associated with spot color inks and plates. However, if precise brand colors are essential, spot color printing may be necessary.

4. REUSE AN EXISTING DIE VS NEW DIE

If your printer has a library of pre-existing die patterns, consider using one of these designs to avoid the expense of creating a new die. Reusing an existing die not only saves money but also reduces the time and effort required for die creation and setup. Check with your printer to see if they have suitable die patterns available for your project.

5. CREATE MACHINABLE FOLDS

Design your folds to be machine-friendly, as machine folding is generally more cost-effective than hand folding. Standard folding machines can handle various fold types, such as roll, letter, gate, and double gate folds. By ensuring that your folds are machinable, you can streamline the production process and minimize labor costs.

<span lang="EN-US" style="font-family:"Arial",sans-serif; 6. USE MACHINE INSERTABLE ENVELOPES

Choose envelopes with machine-insertable flaps, such as commercial or wallet flaps, to simplify the mailing process and reduce labor costs. Machine-insertable envelopes are compatible with high-speed inserting equipment, allowing for efficient insertion of printed materials. Avoid envelopes with pointed, euro, or square flaps, as these may require hand-insertion and increase production time and costs.

<span lang="EN-US" style="font-family:"Arial",sans-serif; 7. CONSOLIDATE YOUR PRINTING

Plan and print a larger quantity of materials at once to take advantage of economies of scale and reduce setup costs. By consolidating your printing, you can save time and money on repeat print runs and benefit from bulk pricing discounts. Additionally, storing excess printed materials for future use can help optimize inventory management and further reduce costs.

8. CHOOSE PAPER WISELY

Selecting the right paper grade for your project can impact both cost and quality. Consider factors such as ink coverage, coating, and intended use when choosing paper. For example, opt for higher-grade paper for premium projects like annual reports, while choosing lower-grade paper for projects with heavy ink coverage to minimize costs. By choosing paper wisely, you can achieve the desired quality within your budget constraints.

Implementing these cost-saving tips can help you optimize your print marketing projects while minimizing expenses and maximizing efficiency.