EMBOSSING VS DEBOSSING: UNDERSTANDING THE DIFFERENCE

When you’re choosing how to make your printed materials stand out, you might hear about “embossing” and “debossing.” These techniques are like silk screening or laser engraving—they make your designs pop and last longer.

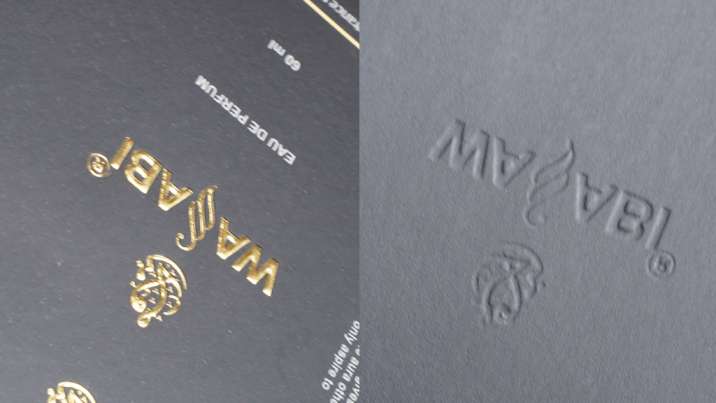

Embossing lifts parts of the paper, while debossing presses them in, creating unique prints that feel different from regular ones. These 3D effects match your design’s style, whether it’s fancy or simple, and make people want to touch and explore the textures.

So, what’s the difference between embossing and debossing? Which is best for your project? Let’s explore these techniques and help you decide how to make your prints even better.

EMBOSSING

Here’s a detailed breakdown of how embossing works and what makes for a quality embossed product:

Process:

- Embossing starts with creating a metal die that has a reversed impression of the desired design.

- The material (like paper or cardstock) is placed between the die and a counter die (often made of rubber) and then pressed together under high pressure.

- This pressure forces the material into the die cavities, creating a raised area on the front side that corresponds to the design.

Enhancements:

- Once embossed, the raised area can be further enhanced:

- Ink: Ink can be applied to the raised area to add color and highlight the design.

- Foil: Foil can also be used instead of ink for a metallic or shiny effect.

- Blind Embossing: If no ink or foil is used, it’s called blind embossing, where the design is simply raised without additional coloring.

- Once embossed, the raised area can be further enhanced:

Quality Considerations:

- Die Detail: A detailed die is essential for sharp and clear embossed designs. The quality of the die impacts the clarity and depth of the embossed image.

- Material Selection: Using heavier weight or textured materials enhances the embossing effect. These materials hold the embossed shape better and provide a more tactile feel.

- Design Impact: It’s important to consider the back side of the embossed product. Embossing creates a “debossed” area on the reverse side, which may affect the overall design layout or require additional finishing.

Examples of effective embossed products include note cards, business cards, luxury marketing materials like booklets, and even stickers for sealing envelopes or enhancing product packaging. Embossing adds sophistication and draws attention to your brand or message.

DEBOSSING

Debossing is a print technique that creates a sunken, or indented, design on your material, which is the opposite of embossing. Instead of raising the design, debossing presses it into the surface.

Here’s a closer look at the debossing process and its uses:

Process:

- Die Creation: Like embossing, debossing starts with making a metal die and a counter-die that match your design.

- Pressing: The material, like cardstock or leather, is placed between the die and counter-die, and they are pressed together.

- Depression: This pressure imprints the design into the material, creating an indented area.

Enhancements:

- Ink: You can add ink to the debossed area to highlight it.

- Foil Stamping: Foil can be used in the debossed areas for a shiny effect.

- Blind Debossing: If you leave the debossed area uncolored, it’s called blind debossing. The focus is on the texture and depth of the design.

Design Considerations:

- Reverse Side: The reverse side of the material will show a raised area. Think about how this affects the overall design. You can incorporate the reverse debossed area into your design to enhance its look.

- Material: Choosing the right material is important. Heavier or textured papers work well with debossing, giving a deeper and clearer impression.

Debossing is commonly used on stationery, business cards, luxury packaging, and book covers, adding a subtle and elegant touch.

The Difference Between Embossing and Debossing

Embossing creates a raised design, while debossing creates a depressed design. Both techniques can add depth and impact to your project, especially when combined with offset printing or foil stamping. Dies for these processes can be sculpted in various ways: single-level, multilevel, sculptured, or with beveled edges, to produce striking, multi-dimensional effects.

Now that you understand both embossing and debossing, you can plan your next project to incorporate the method that best suits your needs. If you’re struggling to decide which process to use, you’re not alone. The next section will help you determine which finish might be the best fit for your project.

Considerations for Choosing Between Embossing and Debossing

Embossing and debossing are great ways to make your printed items more appealing. They add a special touch that encourages people to interact with your materials. Here’s how to decide which technique to use:

Highlight Important Information: If you want to draw attention to key details, use embossing or debossing on specific parts of your design. This will make important information stand out.

Showcase Your Logo: Both techniques can make your logo pop on stationery, letterheads, and envelopes. This adds a professional look that helps your brand get noticed.

Add Texture and Interest: Embossing and debossing add a tactile quality to your print materials. The textures feel good to the touch and make your pieces more engaging.

Convey Value and Sophistication: Embossing can make your items look and feel more valuable. It shows that you care about quality and detail.

Consider these points to decide which technique will best enhance your print project.

Embossing and debossing can both be a great way to stand out among your competitors. Ready to take your print materials to the next level? Contact us today to discuss how these techniques can enhance your brand!

[Bulk Printing, Offset Printing, Commercial Printing, Printing Partner, Printing Service Provider, Printing Solutions, Printers For Corporates, Professional Printing, One Step Print LLP, Offset printer for bulk Printing, Printer Nearby, Embossing, Debossing, Print Finishing, Raised Print Design, Depressed Print Design, Print Enhancement, Custom Print Techniques, Tactile Print Effects, Logo Embossing, Business Card Embossing, Stationery Embossing, Luxury Print Products, Marketing Materials, Custom Die, Foil Stamping, Print Design, Unique Print Projects, Visual Impact, Tactile Experience, Print Collateral]